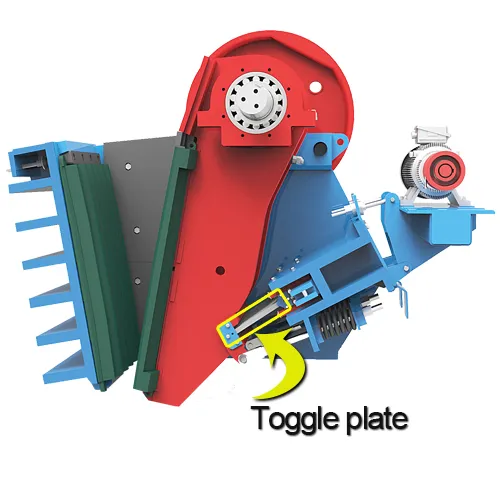

Jaw Crusher Toggle Plate

The jaw crusher toggle plate is a precisely calculated cast iron component used to adjust the discharge opening size and to compensate for wear between the jaw plates, toggle plate, and toggle seat. It is not merely a force-transmitting component but also a safety part for the crusher.

1. Function of the Toggle Plate

The toggle plate in a jaw crusher is a relatively simple component in structure, but its function is crucial. It generally has three main functions: First, to transmit power, where the transmitted force can sometimes be even greater than the crushing force; Second, to act as a safety device—when non-crushable material enters the crushing chamber, the toggle plate breaks first, thereby protecting other machine parts from damage; Third, to adjust the size of the discharge opening.

2. Design of the Toggle Plate

During machine operation, proper lubrication between the toggle plate and its supporting seat is difficult to achieve, and with dust ingress, the condition between the toggle plate and its seat is essentially one of dry friction and abrasive wear. This high load pressure on the toggle plate leads to rapid wear of both the toggle plate and the toggle seat, resulting in a low service life. Therefore, the structural design of the toggle plate must consider both the critical role of this component and its working environment.

3. Types of Toggle Plates

Based on the connection type between the toggle ends and the seats, they can be classified into two types: rolling type and sliding type. A very large compressive force is transmitted between the toggle plate and the seat, along with periodic impact loads. Wear is relatively fast under repeated impact and compression, especially for the sliding type, which is more severe. To improve transmission efficiency, reduce wear, and extend service life, our company designs the toggle ends with a cylindrical surface and the seats with a flat surface. Because the surfaces of both toggle ends share the same cylindrical profile, when the surfaces of the seats at both ends of the toggle plate are parallel to each other, the force on the toggle plate is transmitted along the same diameter of the cylindrical surface and perpendicular to the seat surfaces. During machine operation, the swing angle of the movable jaw is very small, resulting in a minimal angle between the surfaces of the toggle seats at both supports. This allows the toggle plate to maintain pure rolling relative to its seats during operation.

English

English Russian

Russian